A fully equipped laboratory is the foundation of any institution’s infrastructure, especially in fields like science and engineering. A cutting-edge lab provides students with essential tools and hands-on experience necessary for experimentation and research. It not only fosters innovation but also complements academic education, and prepares students for practical applications in their chosen fields. The core elements that underpin this essential infrastructure is outlined below.

The Vehicle Testing Laboratory covers a wide range of vehicle features, from individual component analysis, service, and fault diagnosis, to emissions testing, which forms a “Garage under House”. Student candidates are trained in subjective testing, wherein the vehicle assemblies and sub-assemblies are dismantled, checked, and assembled. In addition to the subjective testing, the laboratory enables the users to perform objective testing methodologies as well. The progressive nature of the laboratory leans towards dynamic testing facilities where the on-road performance assessment of vehicles ranging from mopeds to light commercial vehicles (including three-wheelers) can be tested. The Vehicle Testing Laboratory forms the Automotive Testing Ecosystem, skilling up the student candidates to match the demands of the automotive industry.

Major equipment available

-

Engine compression tester (petrol)

-

Engine compression tester (diesel)

-

Two-wheeler Chassis Dynamometer

-

Computerized Car Wheel aligner

-

Portable Cylinder Reboring Machine Boring

-

Valve Refacer Machine

-

SMS Decarbonizing machine

-

Nozzle Holder Jig Suitable for different types of Nozzles

-

Fuel Injection Calibration Machine Drive

-

Working model of Power Window

-

Car wheel balancer

-

Nozzle tester

-

Bright tyre changer

-

Computerized console for car brake tester

-

Side Slip tester

-

Suspension tester

-

4-wheeler chassis dynamometer

Engine Testing Lab focuses on the development and testing of new kinds of fuels in IC engines. Active research is being carried out on low polluting IC Engines with low carbon alternate fuels, gaseous fuel research, GDI engine research etc. In our laboratory, we have a GDI engine setup and computerized diesel engine testing facilities with AVL emission measurement devices etc.

Major equipment available

-

Computerized fuel system (petrol carburetor type)

-

Fuel system (diesel FIP type single cylinder actual working)

-

Petrol engine 4-stroke 4-cylinder working cut section

-

Engine compression tester (petrol)

-

Abels Flash And Fire Point Apparatus

-

Saybolt Viscometer

-

Cloud And Pour Point Apparatus

-

Cut Section Model Of 2 Stroke Single Cylinder Petrol Engine

-

4 gas analyzer ARAI approved

-

NOx analyzer handheld device

-

Spark plug cleaner and tester Machine

Vehicular structures and driveline systems laboratory provides the basic knowledge, principle of operation and performance of various components and drives in an Automotive Chassis and Transmission system. It help to Understand the basics of Vehicle frames, Front and Rear axles and acquire the fundaments of automotive driveline systems. Through this laboratory, the various components associated with suspension systems are explored and knowledge of braking system, Wheels and tyres is imparted to the students.

Major equipment available

-

Truck actual cut section-motorized

-

Brake adjustment and bleeding hydraulic brake assembly (brake pedal, cylinder, brake drum)

-

Braking system (air brake assembly)

-

Model of driver seat mounted on original hinges on a frame

-

Cut section model of rack & pinion type steering of ambassador (working)

-

Steering system recirculating ball type

-

Steering system worm and gear type

-

Steering system worm and sector type

-

Suspension system front axle cut section working

-

Differential unit complete working cut section

-

Cut section model of the power steering system

-

Cut section model of complete leaf spring type rear suspension system

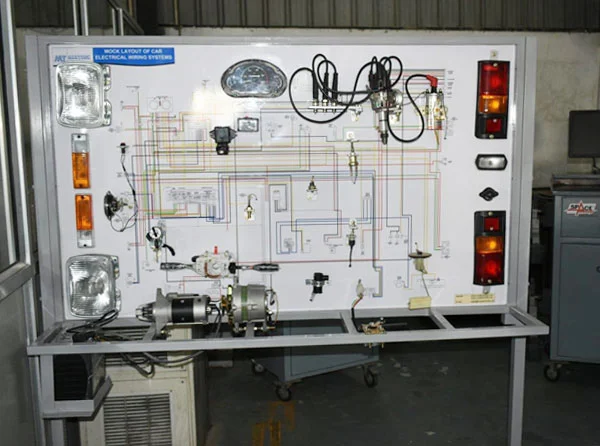

Automotive electrical and electronics system laboratory trains students in the nuances of Electric motor design improvement, Battery thermal management and design improvements, implementation of the cyber-physical system for electric vehicles to enhance its cyber security and online solution and online fault detection of the automotive electric system in vehicles.

Artifact Dissection teaches students about engineering concepts and design principles by having them explore the engineered products around them, to enhance the knowledge of machine tools and improve the skills in common maintenance. It involves studying the intent and function of a mechanical systems like Internal Combustion Engines, sewing machine, washing machines etc. This is effected by disassembling them in order to see how this intent is realized, then reassembling it. This exploration involves having students work in small teams which lead to insight on materials, function, design alternatives, human factors and manufacturing.

Vehicle Dynamics involves the study of the motion of vehicles, the interaction of the vehicle with its surroundings, the influence of forces on vehicles and the response behaviour of vehicles to different road conditions. The complexity of the input and output parameters for vehicle motion is analyzed, and a solution is arrived at. The fundamental concepts derived from the dynamics of machines and systems coupled with the control logic of such systems form the foundation of the subject. Thus, Vehicle Dynamics requires an interdisciplinary approach to solving vehicle motion problems and arriving at solutions.